Learn about the range of 3D printing technologies available and how to find the right 3D printer for your dental lab or dental practice.

3D Printing

Introduction

Additive manufacturing or 3D printing is making digital dentistry a no-nonsense business choice for a growing number of labs and practices, combining high quality and improved patient care with low unit costs and streamlined workflows. The market for 3D printing has been expanding rapidly, bringing this technology within reach for even more businesses.

In light of this expansion, it’s important to ask which technologies are relevant for dentistry and how a practice or lab can make sure they choose the one that’s right for them.

This interactive guide takes a deeper look into dental 3D printing including the latest available dental 3D printing technologies, how to evaluate them, the latest available 3D printers and what to consider before investing in a 3D printing solution.

Dental 3D Printing Technologies

3D printing, also commonly known as additive manufacturing, is an umbrella term that encompasses a group of different printing processes. These processes have resulted in many different types of 3D printing technologies that today’s 3D printers now use.

Some of the most commonly-used are outlined below. Each technology can deliver the precision and accuracy needed for dental applications, but can differ in material selection, surface finish, durability, manufacturing speed and cost.

Stereolithography (SLA, SL)

In stereolithography, a vat of light-cured photopolymer resin is selectively exposed to a laser beam across the print area to build parts one layer at a time. Each layer is traced out by the laser on the surface of the resin. A build platform descends and a new layer of resin is wiped over the surface then the process is repeated. SLA is the most widely used 3D printing technology and generally considered to provide the greatest accuracy and best surface finish. It is ideal for rapid prototyping and cases that require the production of very accurate and finely detailed parts.

Material / Photopolymer Jetting (PPJ)

Material / Photopolymer jetting (also known as PolyJet and MultiJet Modelling) 3D printers work similarly to standard inkjet printing. The inkjet print heads jet liquid photopolymers onto a build tray where the material is immediately cured by UV lamps and solidified which allows layers to build on top of each other until the part is finished. PPJ 3D printing technology produces a very smooth surface which is ideal for aesthetic prototypes, parts and tooling. However, this high quality finish makes PPJ one of the most expensive printing technologies due to the high cost of materials and the large size of the machines.

Powder Binder Printers (PBP)

Binder jet 3D printing, also referred to as powder bed fusion, is one of seven categories of additive manufacturing processes. In binder jetting, a model is built up in layers as the powder bed drops incrementally and a new fine layer of powder is swept over the surface. Colour pieces can be printed and as the model is supported by the powder bed no support material is required. As accuracy is limited the resulting models are useful as study models or visual prototypes.

Digital Light Processing (DLP)

Digital Light Processing operates with the same chemical process as SLA but uses a digital projector as a light source to solidify the resin, rather than a laser. DLP printers have a small footprint, simple workflow, and a wide range of material options, but at a substantially higher cost than desktop SLA printers. DLP parts also tend to show voxel lines – layers formed by small rectangular bricks due to a digital screen – and tend to have a worse surface finish.

How to evaluate 3D Printing Solutions

Accuracy and Precision

Guaranteeing high-quality final parts is the most important concern for a lab or dental practice. The three best measures to take to protect yourself from buying inaccurate equipment are:

- Ask questions.

- Judge accuracy benchmarked on final 3D printed models.

- Order sample parts and judge accuracy and precision for yourself.

Remember that a printer’s accuracy and precision are defined by how well-calibrated all of its systems are, so a system should only be judged on its final printed parts.

Desktop optical scanning allows for the comparison of the organic shapes of printed dental prosthetics to the ‘.STL’ that was sent to the machine. Scans of printed models are scored in terms of the percent of points within a given distance from the nominal point on the ‘.STL’ (e.g. 80% of points within ±50 microns).

Always demand accuracy studies with real scan data of printed parts. Even better, ask for a free sample part or a custom sample of your own design that you can measure yourself against the original design, and judge the quality using free comparison software.

Ease of Use and Reliability

How easy a 3D printer is to use, and how reliable it will be in production are also important considerations. After all, your team is going to have to learn how to use the equipment and maintain it on a daily basis.

- Try to get a sense of the learning curve that will come with a new 3D printer by watching videos online, visiting a trade show, contacting sales, or asking colleagues about their experience.

- Think carefully about the equipment’s setup requirements. Some newer printers are designed intuitively enough to start printing straight out of the box. Other more complicated machines require a service technician to be present during setup.

- Pay close attention to the types of everyday interactions and maintenance the printer will need once it is up and running. Automatic resin dispensing, available on select SLA machines and material jetting printers, can make a big difference in keeping a clean, low-maintenance production environment, and also allows for quick switching between materials.

- Dig deep into published reliability information, and make sure that a manufacturer has appropriate warranties and service offerings to ensure you’ll be taken care of if service is needed.

Costs and Return on Investment

Adopting new technology needs to simply make sense for your business. Remember to consider:

- Upfront costs, including not just the machine cost, but also training and set-up for larger-format machines, as well as potential software licences.

- Running costs, which are best estimated with per-unit material costs.

- Servicing and maintenance costs, which can sometimes include compulsory service contracts and cost as much as 20% of the upfront cost of the printer annually.

All of these factors directly impact on how fast you can make a return on investing in 3D printing technology. The good news is that with smaller-format, lower-cost machines that offer high-output quality, it’s now possible for dental labs and practices to achieve positive ROI within months.

Materials and Applications

Professional 3D printers are some of the most versatile tools found today in dental labs and practices, and the key to their versatility is dedicated materials.

The material selection varies by printer model. Some basic 3D printers can only produce orthodontic models, while more advanced printers can manufacture highly accurate crown and bridge models, surgical guides, castable/pressable restorations, and long-term and biocompatible dental products like splints, retainers, or dentures.

Some 3D printers work only with proprietary materials, which means your options are limited to the offerings of the printer manufacturer. Others have an open system, meaning that they can use materials made by third-party manufacturers. In the case of these third-party materials, it’s important to make sure that the results achieve clinically acceptable quality and accuracy.

Manufacturers release new materials on a regular basis, so there’s a good chance that the printer you buy today will become capable of creating an increasing variety of dental products in the near future.

Throughput and Scalability

Transitioning to digital dentistry should be a gradual process, starting with a single application, and scaling up to multiple applications and workflows step by step. The number of dental products a 3D printer can produce depends highly on the specific model and the application. For example, a DLP printer’s projector exposes layers to light all at once, whereas in SLA printers, the laser has to draw out each part. This leads to an increase in speed for large, fully dense prints. However, the resolution of the projector limits the build volume, so the overall throughput is similar. Enquire with the manufacturer for specific data on multiple applications and scenarios.

Production with multi-machine print cells often reduces upfront costs compared to larger-format machines. By buying one entry-level machine at first, businesses can test out production methods before ultimately scaling up production with demand. This provides the opportunity to pay for production only when it is needed, rather than making large long-term investments in a rapidly evolving market.

Print cells reduce risk through redundancy. If one machine needs servicing, production can be balanced across the rest of the print cell.

Range of 3D Printers

Henry Schein offers a comprehensive range of leading desktop, full production and high speed 3D printers for every size and type of dental lab and dental practice; whatever the capacity and speed requirements, Henry Schein has a solution. Here is just a selection of what is on offer.

PrograPrint PR5

PrograPrint from Ivoclar is a high precision 3D printing system specifically designed for dental applications. The centrepiece PrograPrint PR5 3D printer features a cartridge system to enable easy and virtually contactless handling of the resin materials. Automatic material recognition and an intuitive user interface gives you the reliability you need in printing 3D objects.

- Specially developed light engine for high precision

- Optical status display

PrograPrint Clean

The PrograPrint Clean is designed for cleaning 3D objects with isopropanol alcohol (IPA) and features a self-reversing magnetic stirrer and two stage cleaning option for optimum results.

- Sturdy stainless steel construction

- TÜV tested

- Two cleaning containers for pre- and post-cleaning

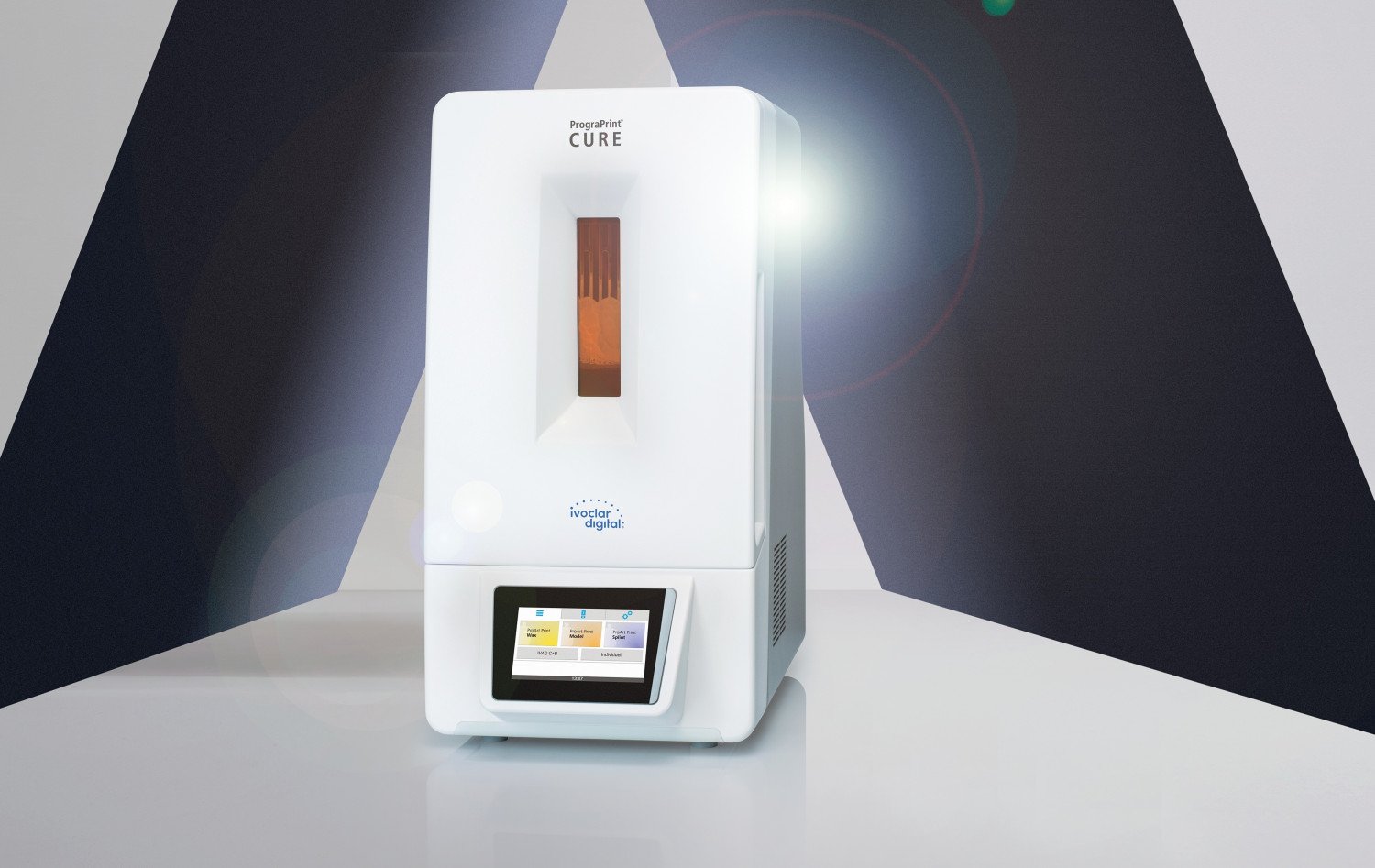

PrograPrint Cure

The PrograPrint Cure is a spacious LED light-curing unit designed for curing printed objects. Its high light intensity can be used for curing lab composites such as SR Nexco® or users can set up their own programmes for a range of other materials they may want to cure in the unit.

- Easy operation via touchscreen

- Optical status display

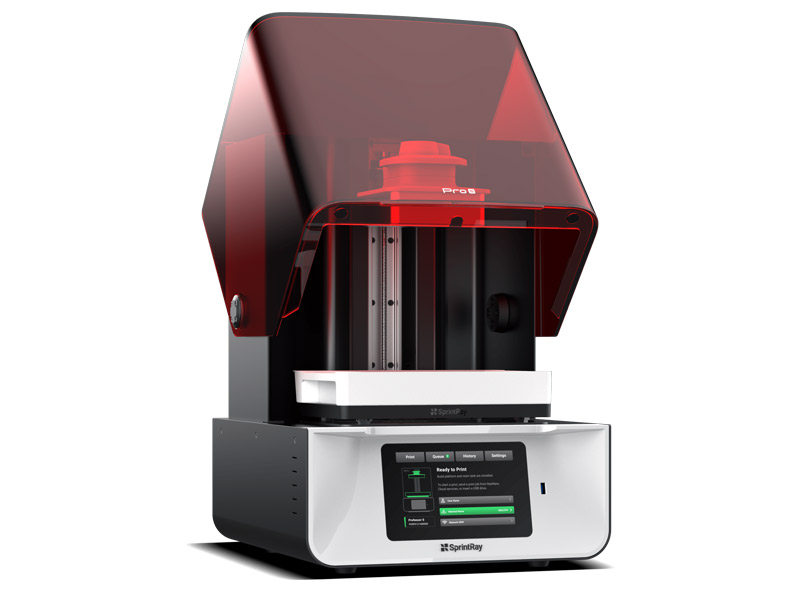

SprintRay Pro S

The SprintRay Pro S is designed to make learning and delegating 3D printing easy. With new and improved user-friendly software, self-monitoring hardware, higher print speeds and large print area, the Pro S is a good choice for everyone, from high-volume dental labs to a practice just starting out.

- New glass projector lens improves uniformity across the entire build platform

- New improved chassis allows for greater Z-axis accuracy and eliminates problems due to spring tension, allowing perfect layers for each print

- New platform heater keeps the Pro S at temperature to ensure maximum adhesion of the build plate to the tank

- New sensor network monitors everything from tank life to reminders to clean the build plate between jobs

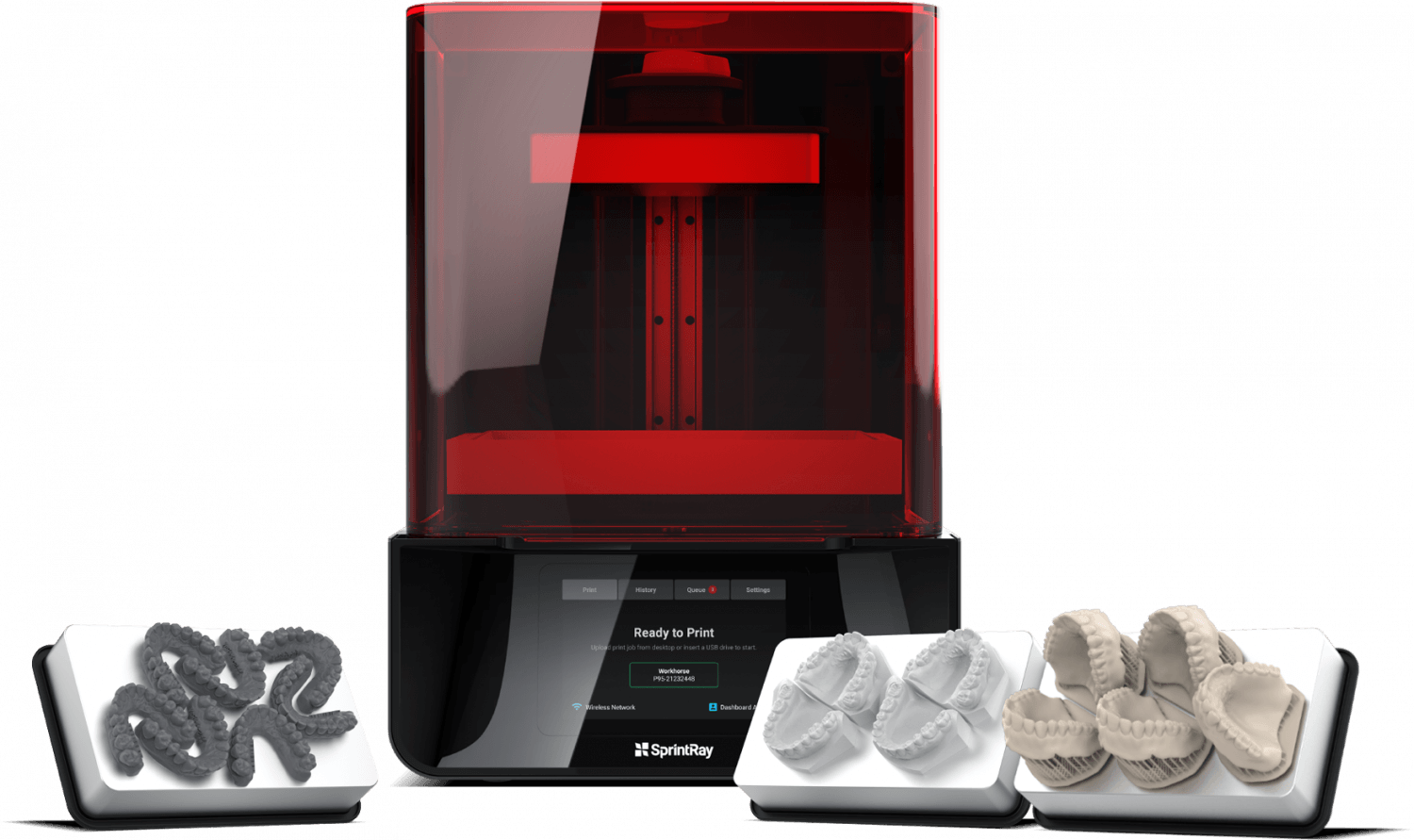

SprintRay Pro 95

The SprintRay Pro 95 is one of the most user-friendly, powerful and reliable desktop 3D printers. Its custom projector delivers high-intensity light uniformly across the entire build surface, ensuring meticulous accuracy. It has the capacity to print up to 30 full-arch models in a single batch for same and next day delivery of a range of appliances including:

- Surgical guides

- Models for aligner production

- Digital dentures and try-ins

- Study and wax-up models

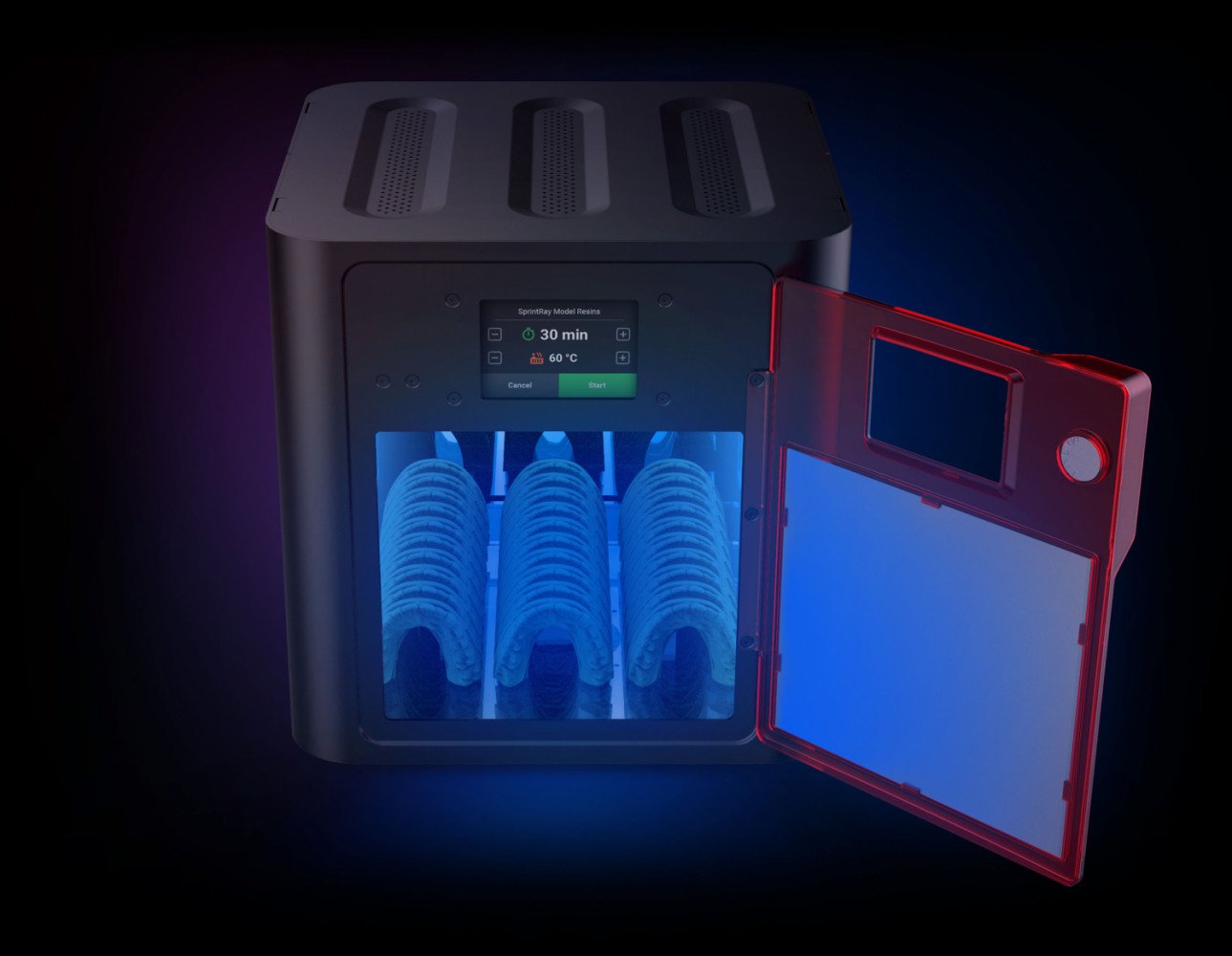

SprintRay ProCure 2

The ProCure 2 is SprintRay’s most advanced post-curing system, fast enough to enable true chairside workflows. Along with a new UVA light module providing 360 degrees of post-curing coverage, the Light Motion Drive delivers more than 25x the power of ProCure 1, capturing the heat generated by the powerful LEDs meaning no time needed to preheat.

- Reduces cure time to 5 minutes or less

- Equipped with Wi-Fi and powerful on-board computer for the latest curing profiles

- Instant heating and active thermodynamics ensures the ProCure 2 is always at the right temperature, saving valuable time

- Chamber scanning ensures each part is evenly and thoroughly post cured

SprintRay ProCure

The Sprintray ProCure optimises the post-curing step to offer the best output in the shortest time. With a 90-watt LED array, sensor-controlled convection heating and omni-directional reflective surfaces, ProCure maximises cross-linking and the mechanical properties of your prints with best-in-class speed.

- 5” touch-screen with a range of 1-touch settings

- Easily add new curing profiles as materials are released

SprintRay Pro Wash/Dry

The Sprintray Pro Wash/Dry is a fully-automated, two-stage wash and dry system designed for dental 3D printing using mechanical jetting to rapidly deliver IPA to printed parts. Automatic pumps recycle dirty alcohol from one chamber to the other and quick-connect hoses drain it away.

- 10 minutes wash/dry

- Fully automated, hands-free process

- Automatic stop/start failsafe

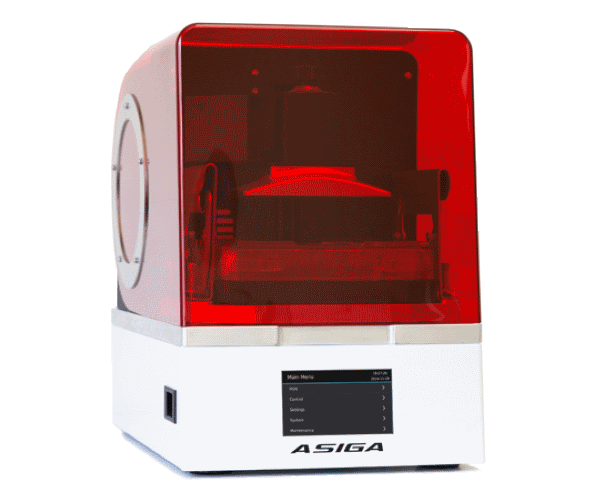

Asiga MAX

The Asiga MAX is a compact and reliable desktop 3D printer optimised for all areas of dentistry from restorative to orthodontics. Print with your choice of any suitable material from any manufacturer to produce crown and bridge, surgical guides, custom trays, dental models, partial dentures and much more.

- Smart Positioning Technology (SPS™)

- High power UV 385nm LED

- Precise material curing

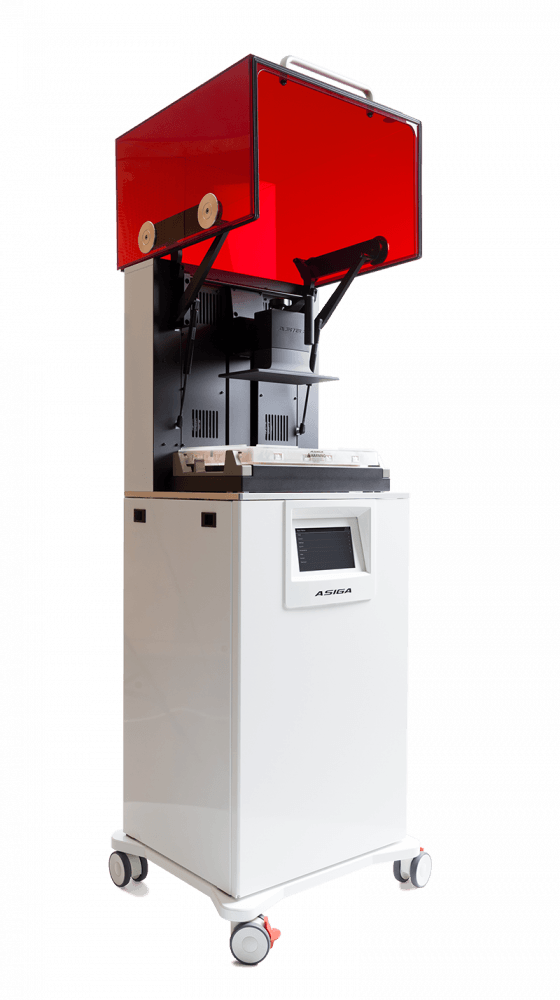

Asiga Pro 4K

The Asiga Pro 4K utilises the latest digital light processing technology (DLP) to achieve the largest build volume in the Asiga range for the most demanding digital manufacturing environments. Asiga’s SPS™ process guarantees every layer is accurately formed using your choice of any suitable material from any manufacturer.

- 4K Super Fast Print Mode

- Custom-engineered optics for precision pixel placement

- Simple touchscreen user interface and multiple connection options

Roland DWP-80S

The Roland DWP-80S combined with Roland’s advanced Quick Denta 3D software makes the production of custom trays, base plates, frameworks and denture components effortless. Once a user imports an STL 3D file, Quick Denta not only detects and repairs minor errors but also takes care of the complete digital set-up.

- Select and print up to 4 different frameworks at once

- Quick Denta calculates the exact amount of resin needed per job

- Easy-to-use 3-step production: Select > Adjust > Print

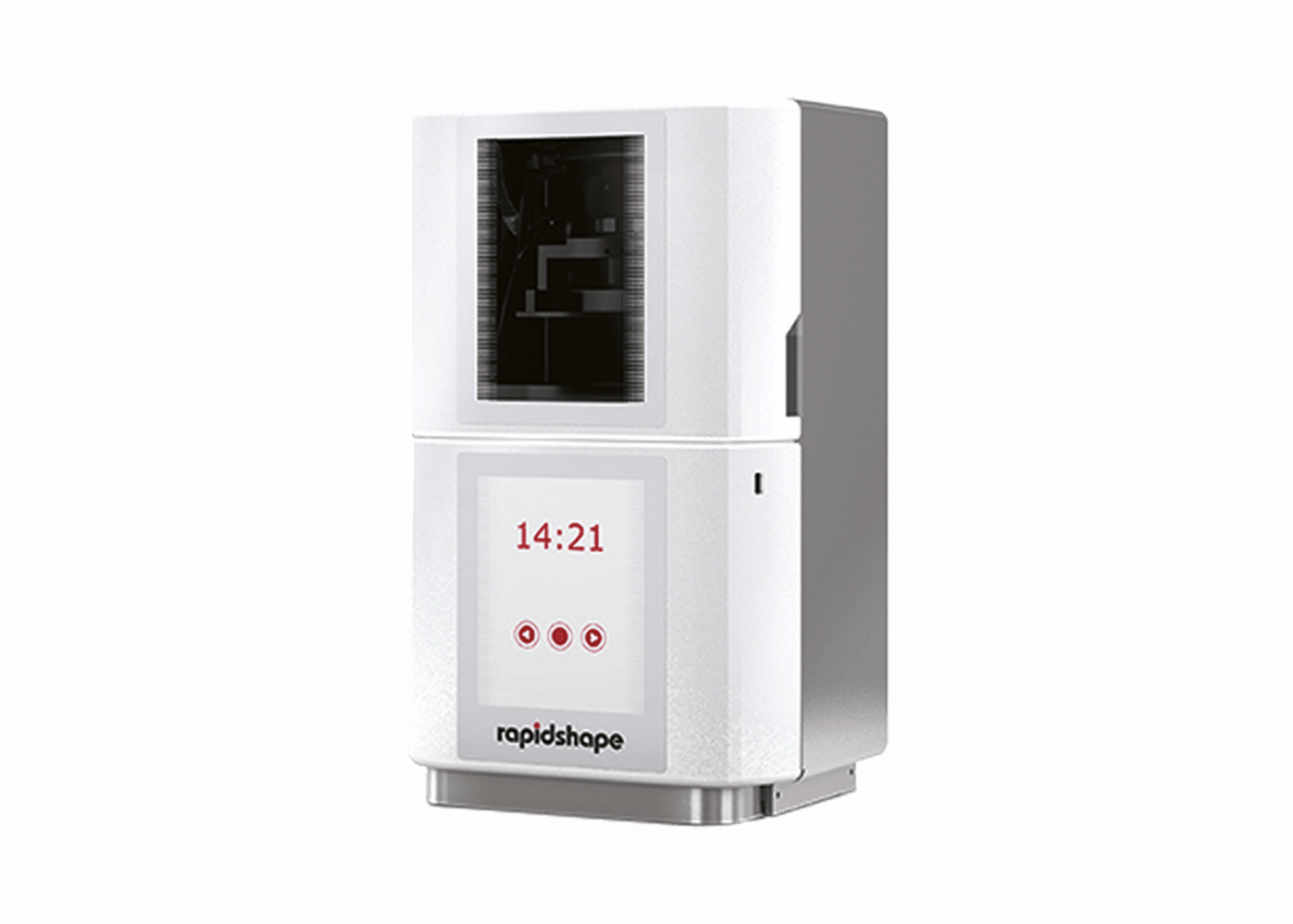

RapidShape D20 II

The RapidShape D20 II offers the most economic professional 3D printing solution for labs with an open material system. Flexible, compact with short production times, the optional high speed Force Feedback technology makes printing times for models within 25 minutes possible.

- The perfect compact unit for small labs

- Certified software interface comes as standard

RapidShape D30+ Ortho

The RapidShape D30+ Ortho features a large build area for production of validated ortho models, individual trays and IBTs. The temperature-controlled resin reservoir provides total process stability.

- Touch door opener and 10-inch colour display

- Patented Force Feed System as standard for maximum production speed

- Fast and precise: print up to 6 models in 20 minutes

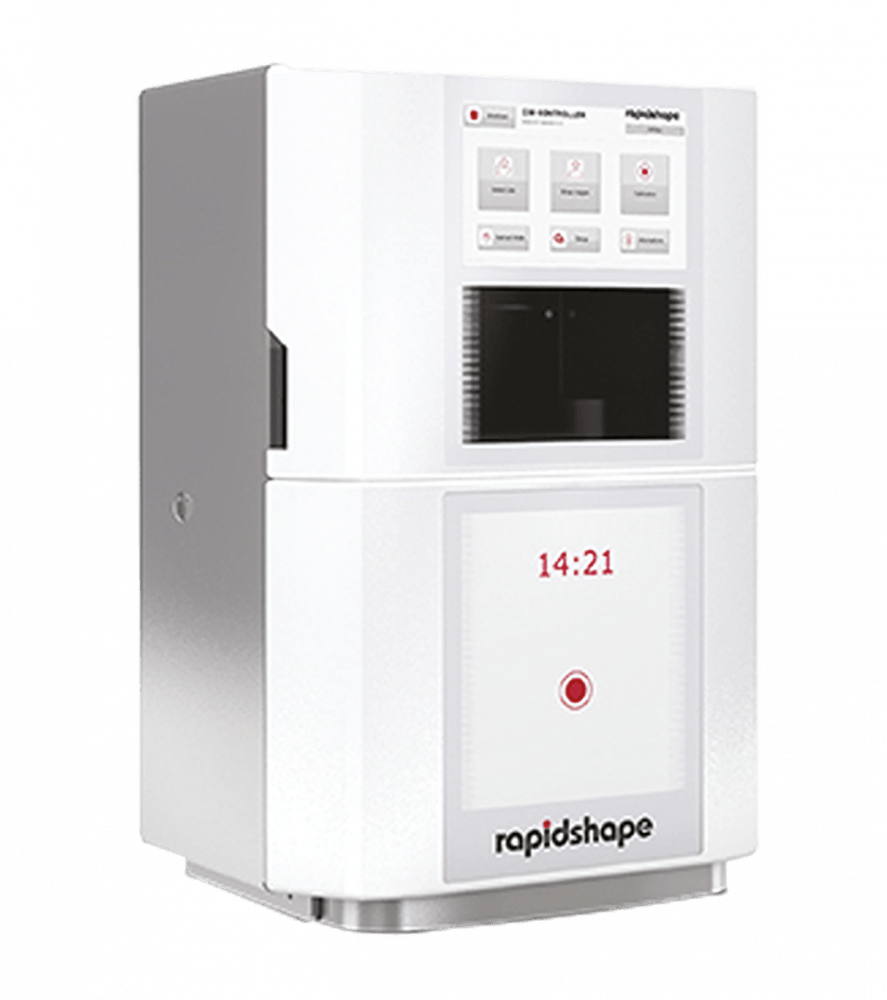

RapidShape D30+ and D40 II

The RapidShape D30+ and D40 II is the powerful, flexible, semi-automated workhorse for professional labs. The simple operation and automatic temperature control allows continuous use without dimensional changes of the final products.

- Touch door opener and 10-inch colour display

- Patented Force Feed System as standard for maximum production speed

- Temperature-controlled resin reservoir

Invest in 3D Printing today!

With thousands of dental practices and dental labs already adopting digital dentistry, there’s never been a better time to start exploring how to take advantage of new technology in your business. While a few years ago 3D printers were only affordable to the largest dental labs, now they are a common sight in labs and practices of any size.

Digital dentistry is developing rapidly, and all dental practices, laboratories and even patients can benefit from 3D printing. It offers seamless integration with intraoral scanners and digital workflows, fast in-house production for many indications and ultimately faster provision of treatment solutions to the patient.

Consider the factors discussed above and the needs of your lab or practice – different solutions might suit some businesses better than others. Make sure to do your research, and consider the cost of running, materials, maintenance and operator training. But remember, with the rapid advances in digital scanners, visualisation, CAD software, milling and 3D printing technologies, it is clear this is an exceptional time for dentistry – and there’s never been a better time to get ahead of the competition!

Our Capital Asset Finance schemes can help you to maximise the Annual Investment Allowance, where you can offset up to £1,000,000 of capital asset spend against pre-tax profits in any full financial year.